The Walrus Islands State Game Sanctuary

The round island yellowfin sole fishery and interaction with walrus

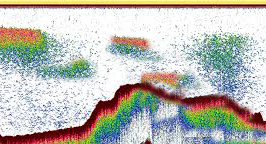

Trawling is like playing several video games at once. The down sounder, sonar, net sonar, radar, plotter, and other electronics are all feeding information to the captain. The dark brown lines in this down sounder picture represents the sea floor. The denser masses of fish are in red.

The Arctic Storm

The “OCEAN PHOENIX” was originally built as a break bulk cargo vessel to Marad Design, C4-S-ls and named S.S. “Oregon Mail”. In 1972 it was converted to a container cargo carrier by Todd Pacific Shipyards Corporation, San Pedro, California, to Marad Design, C6-S-lx, and lengthened 120’ creating new cargo holds Nos. 5 and 6. While in service with American President Lines, the vessel was initially named S.S. “PRESIDENT KENNEDY”. It was later renamed S.S. “PRESIDENT WILSON”.

In 1974, container stowage modifications were made, including removal of mid-cell guides in Hold #6, modification of deck container storage for hatches #2-10 and the addition of permanent ballast in Hold #7.

In 1983 modifications were made to provide stowage for 35’ containers in some rows on deck and below.

During 1989 the vessel was extensively reconfigured by the present owner to a fish processor at Northwest Marine Iron Works, Inc., Portland, Oregon.

During 1992 a crab processing plant was installed aboard the vessel on top of cargo hold No. 3 and crab butcher and giller line was installed on top of cargo hold No. 3.

In 1997, a cod processing module was added atop the fish bins on hatch #5.

In 2005 the Surimi plant was equipped with automation technology to enable operation with fewer personnel and a head and gut processing line was installed in modules 4 and 5A. The capacity of the H&G line is about 150 tons per day. The total freezing capacity on the ship is up to 350 tons per day.

The vessel’s service in processing crab was very limited and the crab processing areas are no longer used. The vessels current service is as a fish processor, with primary product forms consisting of Surimi, fish fillets, head and gut fish, fish meal and Pollock roe.

Since the original outfitting, ongoing improvements and modifications have taken place to improve processing capacity and efficiency.

Copyright 2016 Masende, LLC All Rights Reserved.